System Introduction

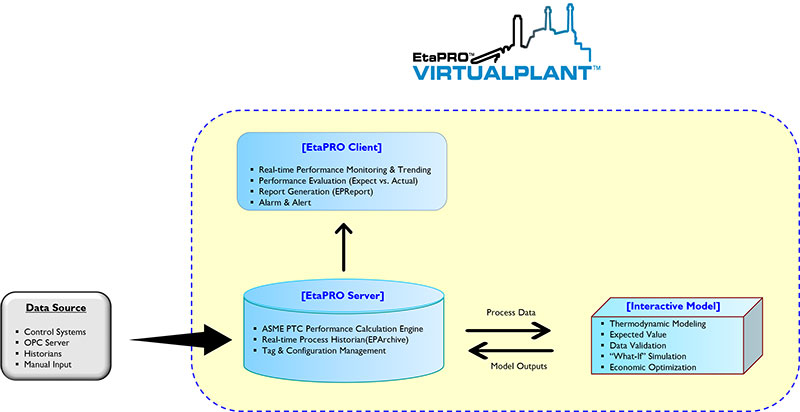

The performance monitoring system implements the power plant cycle as a basic principle thermodynamic model based on the ASME (American Society of Mechanical Engineers) PTC (Performance Test Code). It enables real-time performance calculation, monitoring, and analysis of the facility using data generated from the model. This system evaluates and monitors the performance of the power generation facility by comparing the actual measured values with the acceptance performance test results or the expected values generated from the model.

Main functions

- Real-time performance calculation

- Online/offline performance modeling

- Real-time performance monitoring and trend analysis

- “What-If” Simulation

- Root cause analysis of performance degradation

- Performance Calculation Library (more than 500)

Application Field

- Thermal Power Plant

- Combined Cycle Power Plant

- Nuclear Power Plant

- Hydro/Wind/Pumped Storage Power Plant

- District Heating Power Plant

Use Case

[Efficiency And Heat Loss Monitoring Screen]

[Individual Facility Efficiency Monitoring Screen]

[Plant Cycle Efficiency Monitoring Screen]

[Important Facility Detailed Performance Monitoring Screen]

[Multiple Facility Detailed Efficiency Monitoring Screen]

[Performance Reduction Cause Tracking Screen]