System Introduction

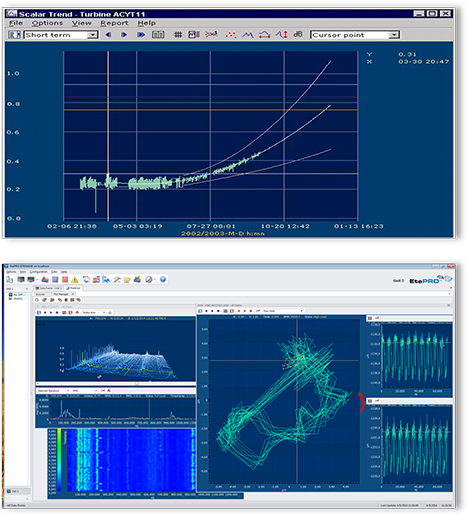

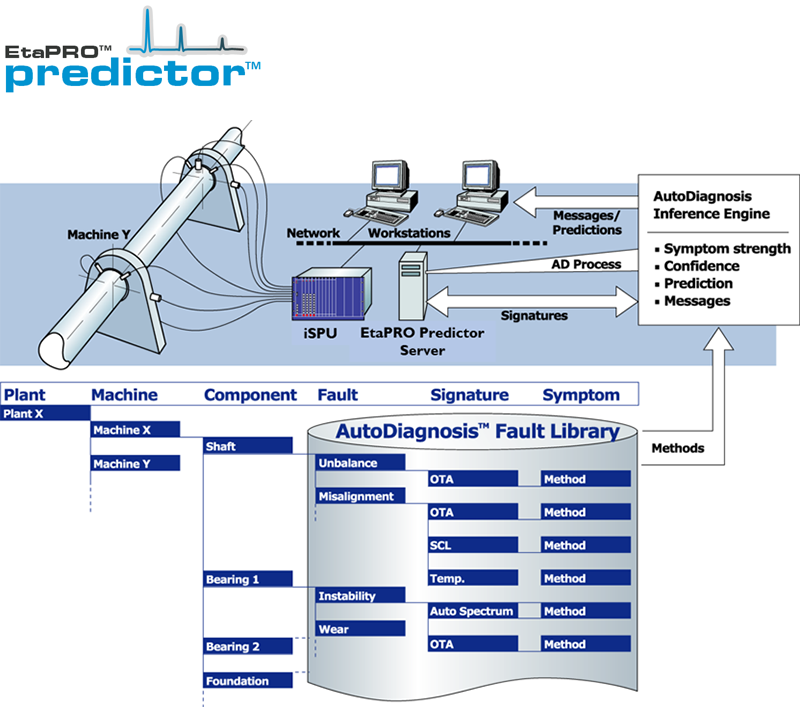

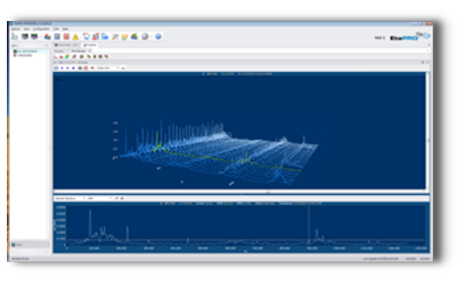

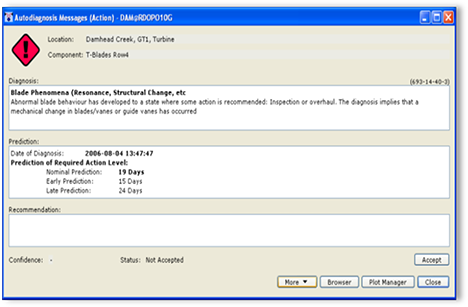

The Rotating Machine Diagnostic System automatically tracks changes in vibration signals to detect faults in rotating machinery early and notifies the user. Results that the system can automatically diagnose include misalignment, imbalance, friction, wear, cavitation, and blade damage, among others. Real-time vibration signals can be analyzed through various types of vibration analysis graphs for both past and current data, allowing for analysis of multiple types of graphs at the point of anomaly diagnosis.

Main functions

- The combination of high-speed data acquisition technology and specialized signal processing techniques results in high-quality fault diagnosis

- Detects the majority of mechanical faults in rotating equipment early.

- Predicts the timing of necessary actions based on the severity of fault.

- Embedded with a variety of automatic diagnosis libraries, such as AutoDiagnosis™ for Fault Library.

Application Equipment

- Gas Turbines

- Steam Turbines

- Compressors

- Large Utility Fans

- Boiler Feed Pumps

- Condensate Pumps

- Cooling Tower Fans

- Cooling Water Pumps

- Other Rotating Machines

Use Case

Vibration Signature

(진동신호 수집/분석)

(진동신호 수집/분석)

Process Data

(운전 데이터)

(운전 데이터)

- Power Output

- Reactive Load

- Exhaust Temp

- IGV Position

- Inlet DP

- Bearing Temp

- Bearing Vibration

- Wheel Space Temps

- Etc.

AutoDiagnosis™

(자동진단)

(자동진단)

Prognosis

(예지분석)

(예지분석)